Doneck’s energy tracking success post-Fit 4 Sustainability

Doneck is one of the latest companies to complete Luxinnovation’s Fit 4 Sustainability programme, which supports companies in their energy transition.

Abigail Okorodus

Abigail Okorodus

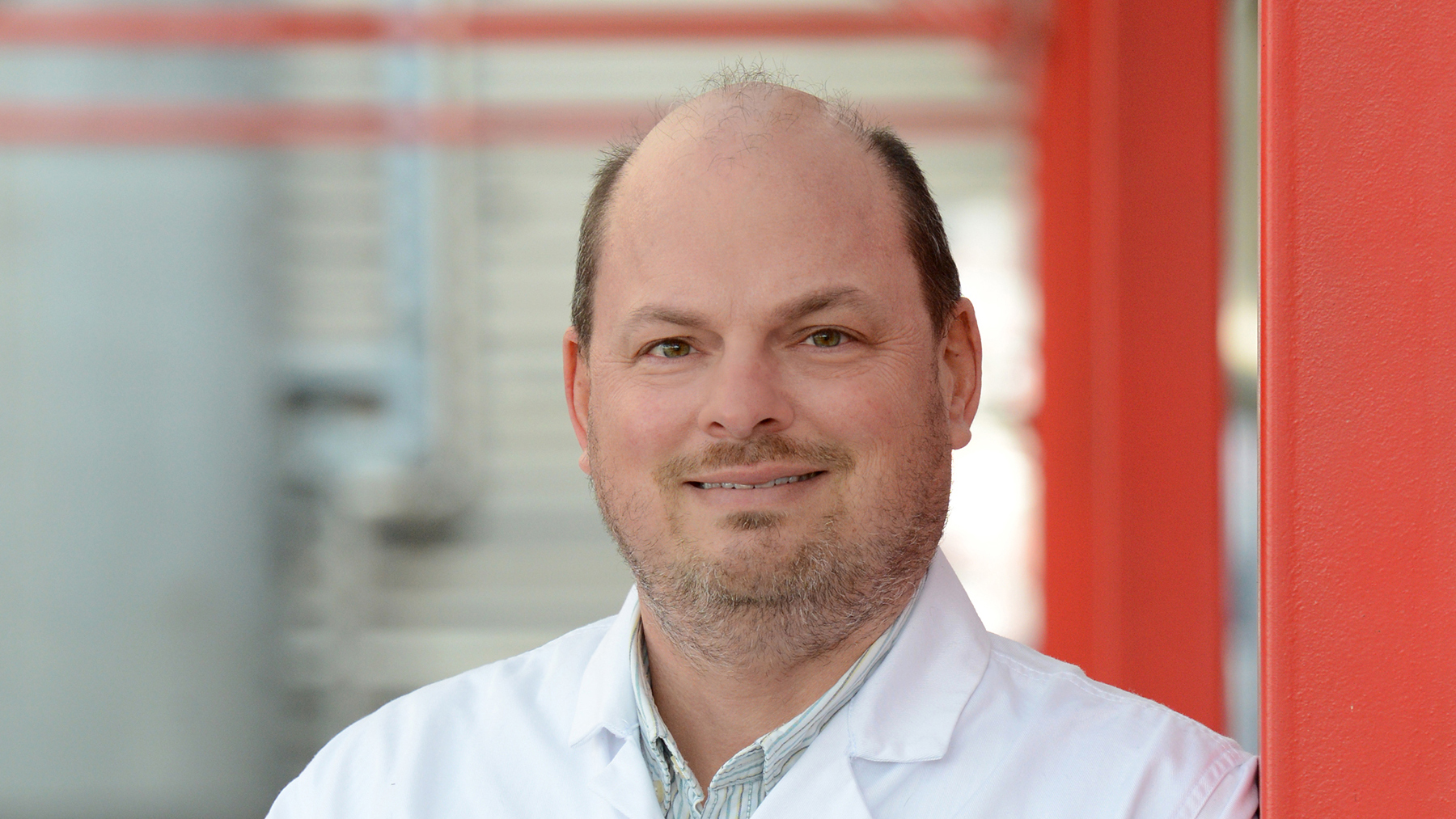

“Sustainability plays since many years a very important role in our company,” highlights Arndt Breitbach, Managing Director of the Doneck network. Established in 1977, Doneck manufactures water and solvent-based flexographic and gravure printing inks for various applications.

“Sustainability plays since many years a very important role in our company,” highlights Arndt Breitbach, Managing Director of the Doneck network. Established in 1977, Doneck manufactures water and solvent-based flexographic and gravure printing inks for various applications.

Annually, the company produces around 60,000 tons of ink at its headquarters in Grevenmacher in Luxembourg. Overtime, it has established a solid presence in seven other countries: Chile, Germany, Hungary, Poland, Spain, the United Kingdom, and the United States of America.

“We initially focused on producing ink primarily for envelopes, but our main market gradually shifted towards various types of consumer packaging. This process is energy-intensive, and with rising energy costs, we recognised the importance of cost-effective projects to ensure a good return on investments and maintain competitiveness in the market,” explains Stefan Blechschmidt, Head of Engineering and Maintenance.

Sustainability plays since many years a very important role in our company.

Arndt Breitbach, Managing Director, Doneck

During the six-months Fit 4 Sustainability programme that helps companies assess and reduce their environmental footprint, Doneck collaborated with consulting firm eco:novis. In 2018, the company had carried out an energy audit by energieagence, and in the last years, it implemented several energy efficiency measures. “We adjusted our heating and ventilation systems to operate only when necessary, especially outside of working hours when no one is in the building. We also took steps to optimise the temperatures in our offices,” points out Mr. Blechschmidt.

Aligning with customer preferences

Apart from energy efficiency ambitions, Doneck joined the Fit 4 Sustainability programme to further align with customer preferences. Raphael Kirn, Quality Management Assistant and Sustainability Officer, remarks, “Customer inquiries regarding sustainability have increased over the past two years. We benefit from the fact that we have partnerships with Luxinnovation and eco:novis.”

Prior to the programme, Doneck also conducted assessments on itself and its suppliers using sustainability intelligence platforms like EcoVadis and IntegrityNext to identify opportunities for improvement. It has also benefitted from the enoprimes programme launched in 2015 for energy-efficient renovations.

Customer inquiries regarding sustainability have increased over the past two years.

Raphael Kirn, Quality Management Assistant and Sustainability Officer, Doneck

“Measures developed by eco:novis as part of the Fit 4 Sustainability programme will further enhance our positive contributions,” asserts Mr. Kirn. Mr. Blechschmidt adds, “We realized it was the time to execute this type of programme as we want to progress in this direction.”

Brainstorming on solutions

Eco:novis conducted a comprehensive sustainability assessment in collaboration with Doneck. This study identified areas for improvement such as the potential for enhancing power generation at the level of the company and optimising its energy usage.

Eco:novis conducted a comprehensive sustainability assessment in collaboration with Doneck. This study identified areas for improvement such as the potential for enhancing power generation at the level of the company and optimising its energy usage.

“When we initiated the Fit 4 Sustainability programme, we thoroughly reviewed our production process with eco:novis to ensure that they understood our operations, energy requirements, feasible projects and those we could not implement. For example, certain aspects of our production process, like merging powder and fluid ingredients, require energy consumption to maintain product quality. So we clarified from the beginning that we are not able to touch that,” mentions Mr. Blechschmidt.

Tracking consumption with eWatch

Nonetheless, the assessment emphasised the need for accurate measurements to boost energy gains. A major outcome following the eco:novis study was the implementation of an energy tracking tool to monitor consumption effectively.

“They did a market analysis of several energy monitoring software systems that could fit within our production and created an offer for these various tools. We then selected and implemented the eWatch tool based on our understanding of these different options,” explains Mr. Blechschmidt.

We can now track the main power consumer within our production.

Stefan Blechschmidt, Head of Engineering and Maintenance, Doneck

The tool provides an overview of electricity, photovoltaic (PV), and gas consumption in the company’s two factory plants. “We can now track the main power consumer within our production, and the periphery around the production to get an idea of where our energy is going to,” he adds.

Using wood waste to generate energy

The assessment also identified opportunities for waste heat recovery and the potential to generate renewable energy from wood waste. Doneck now aims to collaborate with neighbouring enterprises to co-consume the generated energy while supplying power to nearby households.

“Many of our raw materials come in big back packaging, and we have a lot of wooden pellets where the raw material has been shipped on. And the main idea was to transform that waste into energy that can be used on-site. We are in discussions with our neighbour company TMS and have submitted a request to ITM (Inspection du Travail et des Mines) to know what we need to do to complete this project, and they plan to conduct a risk analysis,” says Mr. Blechschmidt.

The improvements proposed by the consultant will also have a positive economic impact.

Emmanuelle Kipper, Senior Advisor - SME Performance, Luxinnovation

The consultant also established contact with a green waste company that can help shred and dry the wooden pellets. “Through this contact, we can get the processed raw material for our machines directly and do not need to build that much here on our site,” he continues.

Luxinnovation support

Both company representatives applauded the support of Luxinnovation. “The interaction was very good, as was the communication with the entire team. This was particularly useful at the beginning, when we had a lot of questions about the conditions of the study, the project framework, and the consultant selection process. Luxinnovation was also very helpful when it came to submitting the application to the Ministry of the Economy which ultimately authorised the project with eco:novis,” underscores Mr. Kirn.

Both company representatives applauded the support of Luxinnovation. “The interaction was very good, as was the communication with the entire team. This was particularly useful at the beginning, when we had a lot of questions about the conditions of the study, the project framework, and the consultant selection process. Luxinnovation was also very helpful when it came to submitting the application to the Ministry of the Economy which ultimately authorised the project with eco:novis,” underscores Mr. Kirn.

“Doneck had already implemented a number of initiatives to promote sustainable development, including their Green Life Ink range and their processes. Working with Eco :Novis has enabled them to take a new step forward, and the improvements proposed by the consultant will also have a positive economic impact”, concludes Emmanuelle Kipper, Senior Advisor - SME Performance at Luxinnovation.