"Production automation and cyber security are inseparable"

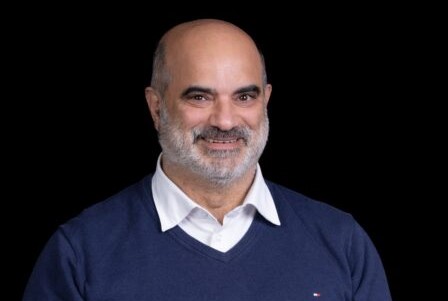

More than ever, cybersecurity is a major challenge for any organisation, regardless of its size or sector of activity. Meet Carmelo Dimauro, National Cybersecurity Competence Center Luxembourg Project Lead.

Jean-Michel Gaudron

Jean-Michel Gaudron

Carmelo Dimauro has a wealth of high-level skills in risk management and business continuity planning and worked for several years at the European Commission. There he acquired extensive experience in supporting policy development, particularly in the field of risk-based decision-making and emergency management planning.

Carmelo Dimauro has a wealth of high-level skills in risk management and business continuity planning and worked for several years at the European Commission. There he acquired extensive experience in supporting policy development, particularly in the field of risk-based decision-making and emergency management planning.

At the heart of the Luxembourg House of Cybersecurity (LHC), the national agency that aims to improve cyber resilience in Luxembourg and develop innovation, skills, collaboration and capacity building in the field of cybersecurity, he is more specifically responsible for managing a cyber risk observatory within the National Competence Centre for Cybersecurity (NC3).

There, he develops innovative approaches and methods for exploiting data and information to support research and innovation activities linked to the Luxembourg ecosystem.

Within the L-DIH consortium, the LHC plays a key role as the sole point of contact for all questions relating to cybersecurity.

Mr Dimauro, you attended the last two editions of the FIC. What did you retain from them?

“I was surprised this year by the greater presence of players producing industrial automation equipment: machines, devices or systems used in manufacturing and industrial processes to automate tasks and optimise efficiency.

These included programmable logic controllers, robotic systems, man-machine interfaces, sensors and other control systems.

In addition to the manufacturers of this equipment, engineering companies operating as systems integrators were also present, and were able to offer automation solutions on the one hand, but also to share the best protection solutions against the risks of cyber hacking.

All this shows that the automation of manufacturing industries will not happen without cyber security.

Do you see an alignment between emerging solutions and the needs of manufacturing companies, particularly SMEs?

“Based on what I saw at the FIC, I can’t say whether there is a great alignment between emerging solutions and the needs of manufacturing companies. What we can perceive, however, is a greater presence of manufacturers and vendors of OT (Operational Technologies) and IoT dedicated to production automation solutions.

In my opinion, this is an important signal of the importance of cybersecurity for the manufacturing industry too. The increasing adoption of automation and digitalisation in manufacturing processes has led to a growing need for robust cybersecurity measures to protect sensitive data, intellectual property and critical infrastructure. I think that’s why the automation industry has such a strong presence at the FIC.

What would you say to SMEs who are afraid of the subject and feel that they don’t have access to current cybersecurity solutions?

“The first thing is that there are solutions for every type of player!

The future will increasingly involve the generation and exploitation of shared information and the definition of automated activities and services.

I don’t think we should fear the future, but we should anticipate it so that we are ready to meet the new challenges it holds in store for us. Human evolution has always been characterised by new technological risks.

At the same time, human beings are also capable of finding solutions to prevent challenges, while taking advantage of technological progress.

At the LHC, whether directly or through contacts established via the L-DIH, we are attentive to the specific needs of SMEs and can provide them with advice and customised solutions.